Basic Color Theory of XCMYK & G7®

Did you know that the most amazing piece of equipment we have and use for color is our eyes? The naked eye can distinguish about 10 million colors. Our eyes tend to be sensitive to slight variations in gray balance shifts, whereas changes in saturated colors are more forgiving to a visual change. In normal lighting, our eyes are most sensitive to the yellow-green area of the color spectrum. This is the main reason you see people working in hazardous areas with this type of vest color.

Red, Green, and Blue, in equal amounts of intensity produce white. This is known as the additive color system. In printing, we are familiar with the subtractive system: Cyan, Magenta, Yellow. A combination of these three colors creates a brown tone, which is complemented by the use of Black to complete the dynamic range of conventional printing—C,M,Y,K.

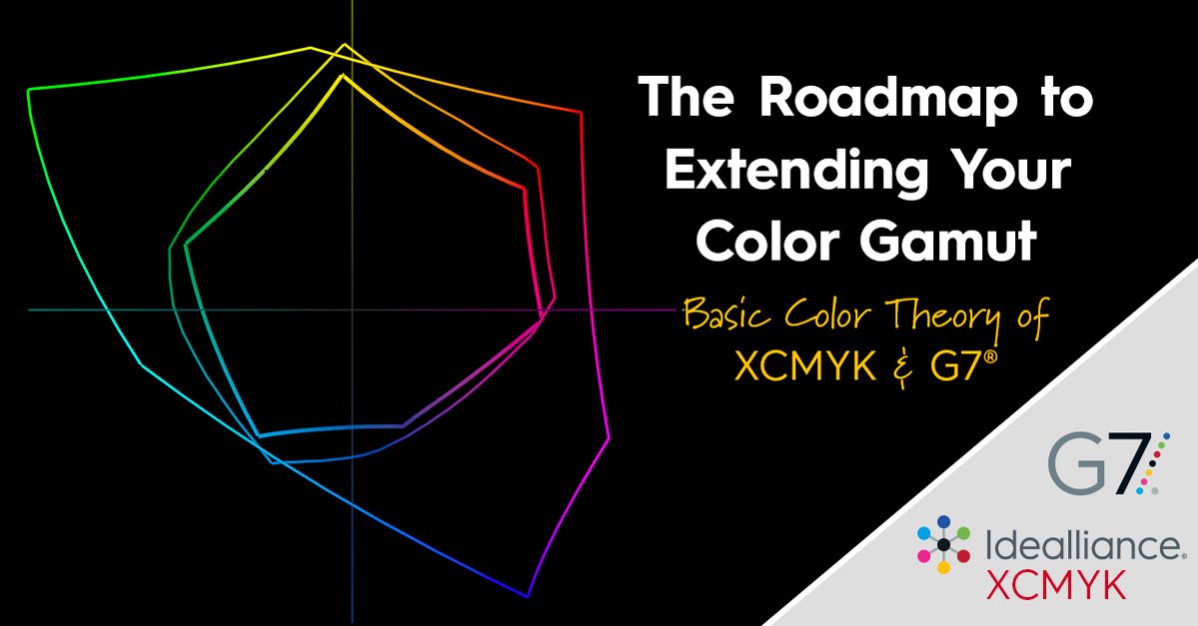

The color gamuts we are most familiar with in printing are RGB and CMYK. The devices that are inherently RGB would be LED monitors, digital cameras, and desktop scanners.

The devices that utilize the CMYK color space are output devices such as sheetfed, web offset, and digital printing presses.

Achieving a near neutral, in conjunction with color management, will give designers, customers, and printers a common expectation whether viewing on a monitor, a contract proof, or a printed sheet in different facilities around the globe.

Extending the Color Gamut

With the onset of inkjet proofing and production devices, as well as grand format devices, we are now capable of printing in a color gamut that is much larger than our traditional offset presses.

These devices are able to reproduce special colors out of the traditional CMYK color gamut, whereas an offset press would have to add a special ink to achieve this. Collateral such as POP signage, brochures, and direct mail, normally contain common imagery which has to be printed across many different platforms such as digital, grand format and inkjet devices. Each device’s color space had to be reduced in gamut to match the offset presses in order to maintain a common appearance throughout each piece of printed collateral.

Enter Extended Color Gamut (XCMYK). Utilizing a G7® 1d curve, we are now able to push ink on press and add additional ink film thickness, creating more density. By creating a G7 curve at these higher densities, we maintain a neutral appearance and visual tone shape while extending the gamut of conventional CMYK inks. Its color space is 46% greater than GRACoL2013 (CRPC6). This now enables the devices with greater gamut capabilities to be utilized to their fullest capacity.

Achieving a near neutral, in conjunction with color management, will give designers, customers, and printers a common expectation whether viewing on a monitor, a contract proof, or a printed sheet in different facilities around the globe. The “extended” XCMYK gamut basically adds more visual colors while utilizing the same CMYK inks. This is done through adding more ink on press and using the near-neutral G7 methodology to create tone shape and Gray Balance.

Whether you are using a spectrophotometer to verify neutrality or creating a 1D curve that represents proper tone shape and gray balance on press, the variations of color gamuts will rely on a near neutral gray to create a common appearance in reproduction.

The key benefits, being able to achieve special colors on press that would normally require special spot colors, now can be accomplished with a standard CMYK ink set. This results in competitive pricing for the customer coupled with lower production costs. Additionally, utilizing extended gamut (XCMYK), designers would be able to create in different ways that would feed into a customer’s color palette for branding and product promotion.

The old saying that has been used in the printing industry for years, “Clean and Bright is always right,” still rings true with XCMYK, keeping printed collateral colorful and visually exciting to the observer’s senses.

Learn more about color management specifications for printing

XCMYK is an extended-gamut CMYK printing method that yields a much wider color gamut than regular 4-color printing.

G7® is Idealliance’s industry-leading set of specifications for achieving gray balance and is the driving force for achieving visual similarity across all print processes.

GRACoL® is a set of guidelines and recommendations to help print buyers, designers, and specifiers work more effectively with their print suppliers.

Expanding the Color Gamut Further

The Idealliance Global ECG (Expanded Color Gamut) is designed to make 7 color process printing as predictable and normal as current CMYK printing specifications such as GRACoL and SWOP. The ECG characterization chart is for use in characterizing and calibrating multicolor print processes. The ECG project is to establish global characterization charts and processes for multicolor print processes.

Download the Idealliance ECG Characterization Test Target Project Kit »