Wide/Grand Format Inkjet Performance Benchmarking

The Idealliance Wide/Grand Format Inkjet System Performance Benchmarking Program is an initiative to quantify performance of innovative technologies to evaluate original equipment manufacturers’ large format printing systems for printing, production, and application qualities for a specific ink and media combination. Results of the program allow developers to conduct independent third-party analysis of current and emerging technologies and inform prospective and current users of large format technologies on which system best meets their production and market needs, as well as how to achieve consistent quality from their printing systems.

Submissions are evaluated according to Level (1 or 2) for:

Level 1

Vendor Testing & Idealliance Evaluated Printed Sheets

Color Accuracy

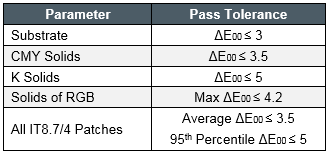

Using an IT8.7/4 target, the following tolerances are evaluated according to the G7 Master Press Color Space Pass/Fail Criteria.

Eleven reference data sets are for use: GRACoL 2006c1, SWOP2006c3, SWOP2006c5, SWOP2013c5, CRPC1, CRPC2, CRPC3, CRPC4, CRPC5, CRPC6, CRPC7

Uniformity

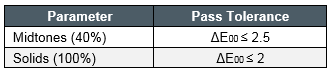

Using three levels of gray uniformity test pages, an M-Score is determined as per the Idealliance Digital Press Certification.

Pass/Fail criteria:![]()

The highest M-score of the three targets is used for reporting.

Repeatability

Idealliance ISO 12647-7, 3-Row Digital Control Wedge 2013 is printed on four (4) sheets, at three (3) intervals: Hour 0, Hour 3, and Hour 6 with date and time stamp.

Pass/Fail Criteria:

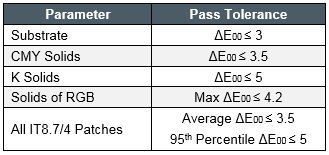

Color-to-Color Registration

Registration targets are printed on the corners of the 12″ x 18″ test sheet and measured. Following the Idealliance Digital Press Certification pass/fail criteria;

![]()

The highest cyan, magenta, or yellow measurement value is reported.

Print Speed

Actual print speed and print speed recorded via video of actual print sheets with timer and printer setup screen.

Testing Parameters

Paper used should be Glossy Coated media with a thickness no less than 9.0 pts/mils or 23 microns.

Device settings should be configured to deliver the highest quality reproduction, all settings reported shall be on this configuration.

Level 2

Independent Idealliance Partner Testing

Color Accuracy

Using an IT8.7/4 target, the following tolerances are evaluated according to the G7 Master Press Color Space Pass/Fail Criteria.

Eleven reference data sets are for use: GRACoL 2006c1, SWOP2006c3, SWOP2006c5, SWOP2013c5, CRPC1, CRPC2, CRPC3, CRPC4, CRPC5, CRPC6, CRPC7

Uniformity

Using three levels of gray uniformity test pages, an M-Score is determined as per the Idealliance Digital Press Certification.

Pass/Fail criteria:![]()

The highest M-score of the three targets is used for reporting.

Repeatability

Idealliance ISO 12647-7, 3-Row Digital Control Wedge 2013 is printed on four (4) sheets, at three (3) intervals: Hour 0, Hour 3, and Hour 6 with date and time stamp.

Pass/Fail Criteria:

Color-to-Color Registration

Registration targets are printed on the corners of the 12″ x 18″ test sheet and measured. Following the Idealliance Digital Press Certification pass/fail criteria;![]()

The highest cyan, magenta, or yellow measurement value is reported.

Print Speed

Total printing time (document print command issued, to device rest) and image time (Initial head movement to imaging complete) for each production mode for the device will be tested and reported.

Speed modes may be independent of approved G7 condition.

Ink Consumption

Testing of ink consumption will be completed in the highest quality production mode of the device (in G7 conformance)

Brand new (full-set) cartridges will be weighed before installing in an established device, and will be remeasured upon completion of a standard set of printing images. The standard image set is defined as 100 prints of 2 pages form the 11′” x 17″ G7 forms. Pages will be arranged to maximize utilization of the media. Differential weight will be reported for the total ink usage over all cartridges (Sum).

All device conditions and settings will be captured and documented as part of the testing.

Testing Parameters

Two options for testing:

Vendor can choose to have third party consultant perform onsite Level 2 Independent Partner testing. Please call Idealliance for quote, 703-837-1070.

- Device can be shipped to Idealliance’s independent evaluation lab, Rochester Institute of Technology Printing Applications Laboratory. Device supplier will be responsible for shipment of the device, materials, and return shipment when desired.

Device will be established to G7 color-space conformance referencing CRPC6 in Highest Print Quality Mode.

Testing will be completed with a consistent paper grade among all devices. Standard paper grade is defined as:

- 80 lb Cover or Equivalent thickness (9 pt/mill, 23 micron)

- CIELab values in agreement with CRPC5 or CRPC6

- Substrate gloss will be a semi-gloss sheet with 60 Degree gloss between 15-30

- Sized to match the maximum dimension of the device

- Will be comatible with and have good perofmance with the device/ink set

All measurements will be completed with M1 measurement mode